Three Ways Machine Vision Systems Can Make Your Manufacturing Process Smarter

3 Mins Read

Published on: 15 September 2022

Last Updated on: 21 February 2025

toc impalement

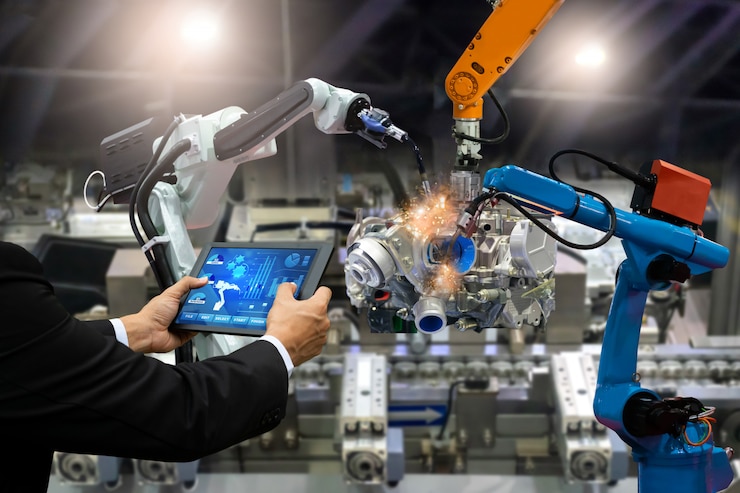

Compared with human eyesight, machine vision has many advantages, including high speed, objectiveness, high precision, supervision, indefatigability, and environmental restriction.

All of these attributes can be deployed to make your manufacturing process smarter.

Advanced machine vision systems are often used for measurement, inspection (presence detection, defective product detection, digital statistics, defect detection), positioning, and identification.

Mission vision system applications are vital to consider the best practice to ensure that all vision system processes and hardware work together in a consistent manner.

Machine Vision System: Three Ways You Can Make Your Manufacture Process Smart

Machine vision systems are also known as automated vision systems. Each component has an individual function. When they work together, they each have a distinct role in the machine vision system.

Here are three ways machine vision solution companies have already adopted to make your manufacturing process ready for the twenty-first century:

1. Easily Implement Pick-And-Place With Machine Vision-Guided Robots

1. Easily Implement Pick-And-Place With Machine Vision-Guided Robots

Industrial robots are already in heavy use. With the birth of collaborative robots and rapid improvements in 3D machine vision, they are being further exploited, especially for machine vision-guided robots.

3D machine vision has high demand in the machine vision systems market. Including a vision system in the pick-and-place robot allows it to monitor the products and anything sent on the conveyor system, reducing many errors throughout the process.

It helps locate the faulty product, which is sorted from the batch of refined products by place robot designated and another pick for the job. Machine vision identifies the object’s precise location and transmits these coordinates to the robot.

Significant advancements in vision/robot interfaces greatly facilitate this process. As a result, 3D robotic vision is particularly suitable for pick-and-place applications.

2. Embedded Machine Vision Enables Low-Cost Integration

Embedded programming is a specific type of programming that supports creating consumer or business-oriented devices that do not run on traditional operating systems like laptops and high-end mobile devices.

Small embedded processing boards, usually based on the ARM architecture, offer multiple possibilities for developing machine vision embedded in other equipment and manufacturing processes.

Streamline operations, reduce costs, and enhance productivity with cutting-edge Manufacturing Process Optimization strategies. Stay ahead of the competition by leveraging the latest techniques and technologies.

Many machine vision libraries and toolkits are now compatible with these platforms, allowing a more comprehensive range of vision solutions in this form factor.

| Note: Combining these processing capabilities with low-cost cameras, such as board cameras, provides machine vision systems to be integrated into many products and processes at a relatively low cost. |

3. Optimisation Of Production Line Quality Control

Quality control by machine is a process that consists of taking photos in an automated way on all or part of a production chain to control the conformity of the visual aspect of a product. Machine vision equipment is mainly used in the food and bottling sector.

Inspection by industrial vision on a production line or packaging line is a well-established practice.

There are different types of systems: the product ranges from stand-alone smart cameras that perform an inspection task and transmit a positive/negative result to the control system to PC-based systems with multiple cameras and inspection posts.

Machine vision systems can be adapted to existing lines or integrated into new ones. You can also combine machine vision control with statistical methods of process control.

Machine vision solution companies adopt these three ways They are used to verify critical measurements and analyze trends in them. Interventions can thus be carried out to adjust the process before an inferior product is produced.

Additionals:

Comments Are Closed For This Article