IoT Will Make Warehouses More Efficient & Safer In These 3 Key Ways

5 Mins Read

Published on: 05 July 2021

Last Updated on: 15 November 2024

toc impalement

The Internet of Things is a revolutionary technology that is changing the way we live, work, and play. With the IoT revolution in full swing, it’s not surprising to see this new technology making its way into warehouse operations too.

Both transportation and healthcare seem very excited about the rise of the Internet of Things, commonly known as IoT. Even in warehousing, IoT is becoming a reliable option. So, does this mean IoT is the future of warehousing?

The Internet of Things is a revolutionary technology that is changing the way we live, work, and play.

With the IoT revolution in full swing, it’s unsurprising that this new technology is also being used in warehouse operations. In simple words, IoT orchestrates the warehouse operation.

Everything from ensuring that your weighing machines are accurate to training workers on safety-related issues can affect productivity and output.

Experts point out that corrosive scales can play a valuable part in ensuring longevity and cutting down on recurrent costs in any warehouse setup.

The Concept Behind IoT And IoT Sensors

IoT, also known as the Internet of Things, is a collective network of various devices and technologies. Its major role is to facilitate communication between devices and the cloud.

In some cases, the network is also established between devices.

This entire ecosystem of various smart items has the capability to capture and exchange data, such as location, temperature, etc., in real-time.

The complete IoT system comprises small devices like sensors that detect variables like humidity, movement, pressure, temperature, etc., and later convert these into real-time data.

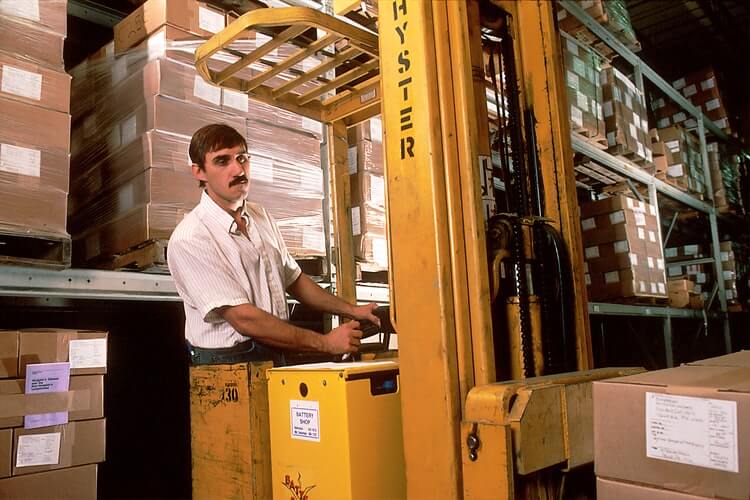

RFID is one of the common sensors attached to packages. With RFID, companies can easily track packages stored within the warehouse. Moving companies also use motion sensors for forklifts to control their motion.

As the IoT sensors are connected to each other, they are capable of collecting and exchanging data. So, you can put the data in computers to analyze and streamline your warehouse operation.

How Does IoT Work In Warehousing?

The Internet of Things, or IoT, mainly uses internet connectivity to connect smart devices, sensors, etc., to form a network. This network helps in tracking the entire inventory, monitoring their conditions as well as optimizing the warehousing processes.

So, you can collect the transmitted data and pass it through a system to transform it into real-time comprehensible data.

Managers can use the data to make informed decisions, on how to keep everything organized, avoid stock out or overstocking, and know exactly what they need to implement for the warehouse.

In this article, we will talk about how IoT will make warehouses more efficient and safer in these three key ways:

1) Remote Monitoring Of The Warehouse

Remote monitoring of the temperature, humidity, and air quality in a warehousing environment is now possible through IoT technology.

This provides real-time data on what’s happening at any given time within an enclosure, allowing for more accurate and efficient control overheating, cooling, or ventilation systems, and alerting staff to potential problems before they escalate.

In this way, warehouses can be made safer by reducing fires or chemical spills resulting from faulty equipment such as refrigerators that malfunction due to incorrect temperatures being set.

The Internet of Things also can provide remote surveillance of dangerous environments like those found in factories that process hazardous substances meaning risks are lessened when it comes to things like injuries caused by missing safety protocols getting overlooked because somebody wasn’t there to see them happen.

The Internet of Things can also be used to help remote workers feel safer by providing a constant connection with their colleagues in the office whereby they can speak and receive messages at all times when out on-site rather than having to rely solely on email or phone calls which could miss one another’s messages due to timing issues.

Besides ensuring warehouse safety through monitoring, IoT ensures that machines and materials are always in the right place at any given moment. This way, one can eliminate wasteful practices like walking around to find a particular tool or part.

2) Alerts & Notifications

IoT can also be used to set up alerts and notifications by setting a system-wide rule that automatically shuts off any equipment exceeding a given temperature.

A warehouse operation generally includes a wide range of tasks. Successfully integrating IoT can increase the process’s efficiency and safety.

IoT also helps create a safe environment for workers so that they can do their jobs effectively and without mistakes.

Once you integrate IoT into your warehousing operation, you will no longer need many workers to work simultaneously. This solves storage issues and reduces potential hazards.

In addition, warehouses can now be equipped with an automated inventory system with an alert mechanism for when stock should be updated. This means that staff members do not need to do any manual counting.

This prevents running out of important supplies or food items and prevents misplacement or loss of items.

3) Predictive Maintenance And Analytics

IoT-enabled technologies can help predict when equipment will need maintenance, whether it’s a forklift or an industrial robot. That means there can be fewer surprises and more efficient use of resources – so the warehouse becomes safer while also being more productive.

Furthermore, the IoT can help proactively monitor the performance of machines, providing valuable information about when their service life is coming to an end. That means there will be more up-to-date equipment in warehouse settings and less downtime for any staff members or workers who might depend on them.

With predictive analytics taking care of routine tasks, more staff members will have time to focus on higher-level responsibilities like creating strategies for improving customer experiences and making supply chain decisions.

These analytics will also reduce staffing requirements, thereby making warehouses cheaper to run.

4) Enhances Security And Protects Assets

The IoT sensors are capable of monitoring the warehouse’s accessibility. The sensors also help you track your asset movement and keep you updated about weather conditions.

Once you integrate the sensors, it becomes easy for you to prevent theft and ensure the integrity of the products.

With the help of these sensors, you can gather different data and send alerts in real-time. As a result, you can reduce the security breaches and create a safe environment.

5) Reduces Overall Costs

Iot offers a predictive maintenance system that allows you to foresee different kinds of equipment malfunctions in your warehouse. Once you enable the IoT maintenance system, it proactively helps repair and reduce defects in equipment.

So you can streamline your process while minimizing the risks.

IoT also enables climate control systems that work to reduce massive energy consumption.

Conclusion

A diverse range of tasks are typically handled in warehouses, which has huge implications for efficiency and safety; safer conditions mean fewer injuries, which means more workers can do their jobs effectively with fewer mistakes and delays caused by fatigue or injury. IoT can help any warehouse achieve this through remote monitoring, alerts and notifications, and predictive maintenance and analytics.

It’s clear why adopting The Internet Of Things could be advantageous for your business. You should either be already implementing it or behind the curve when it comes to innovation. If you want to include IoT in your warehouse operations, hire the professional services of NetSuite Consulting to help you make the process as seamless and painless as possible.

Read Also:

Comments Are Closed For This Article