5 Industries That Leverage Laser Technology For Innovation

06 November 2023

4 Mins Read

toc impalement

Innovation can help businesses stand apart in a competitive space by paving the way for quick gains and sustainable growth. More than giving businesses a competitive advantage, technology can help them achieve their goals sooner rather than later.

For example, going hybrid kept companies afloat during the pandemic. Many organizations have decided to embrace the model for good to save operational costs and increase their bottom line.

When it comes to industrial innovation, laser technology emerges as a game changer. According to statistics, the global laser tech market is likely to reach a massive $ 35.4 Billion between 2022 and 2032 at an impressive growth rate of 7.8%. The numbers indicate how valuable this technology is for businesses.

Here are some industries that can rely on laser technology to drive groundbreaking innovations, revolutionize processes, and create new possibilities.

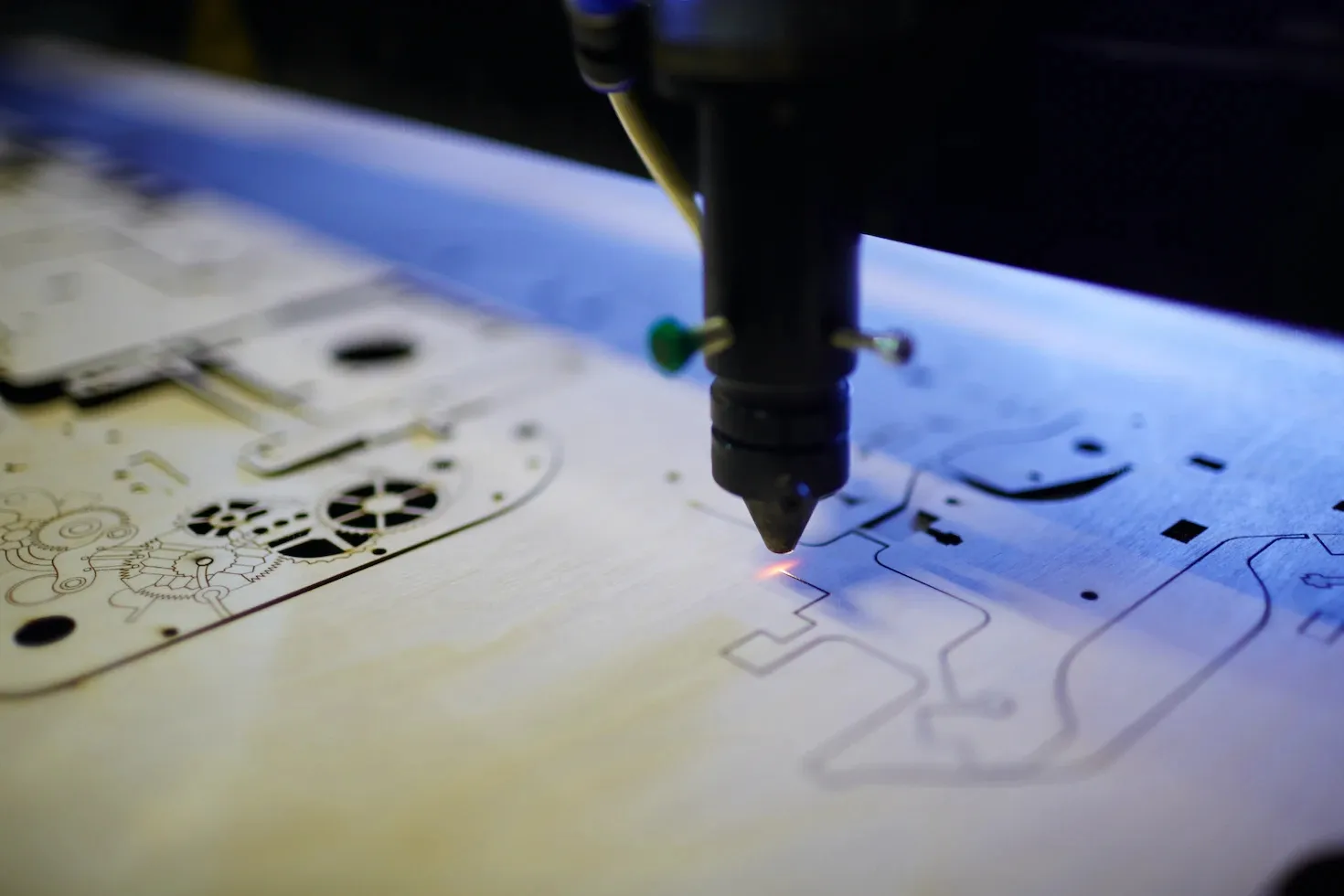

Manufacturing

Quality Magazine notes that laser material processing technologies have been around in the manufacturing industry for a decade. Manufacturers can depend on it to achieve top quality without compromising production speed and cost. Laser processing solutions serve as the foundation of precision manufacturing, ensuring consistent, highly accurate performance every time.

Laser cutting and engraving machines help with designing intricate patterns on materials such as plastics, metals, and textiles. The technology also supports additive manufacturing processes like 3D printing to create complex and customized components. Laser marking, cleaning, texturing, and heat treatments are other manufacturing applications of this technology.

According to Novanta Photonics, laser systems have the potential to push industries forward with efficient workflows, better product quality, and less waste. Manufacturing companies shouldn’t miss out on this game-changing innovation.

Packaging And Labeling

Besides improving manufacturing processes, laser technology takes the packing and labeling industry a long way with innovation. For example, laser marking facilitates direct marking and coding on packaging materials. It ensures permanent, high-quality markings and speeds up the processing of products on production lines.

Laser-cut packaging designs can create unique shapes and openings for unique branding opportunities. Engraving solutions can incorporate security features like intricate holograms and micro-text to prevent the counterfeiting of high-value products. These security elements are impossible to tamper with, reducing the risk of counterfeiting.

Sustainability is another benefit of laser tech in the packaging industry as it enables the processing of biodegradable plastics and reduces waste with precise cutting and marking.

Healthcare And Medical

Laser technology has transformed the medical and healthcare sector in many ways, from diagnostics to treatments and surgeries. Medical lasers ensure precise and minimally invasive procedures. These procedures minimize tissue damage, limit recovery times, and enhance the overall effectiveness of medical interventions.

Eye surgeries (LASIK), dermatology (skin resurfacing and hair removal), dental procedures, and cancer treatments are a few examples of the technology’s use. Optical Coherence Tomography (OCT) is a laser imaging technique that helps with early detection and monitoring of diseases.

Laser processing is also an integral part of medical device manufacturing processes. Over the years, it has been used to improve device designs, efficiency, and compliance through applications like laser cutting and marking.

Aerospace And Defense

Laser technology is instrumental in the aerospace and defense sector. It has diverse applications, from materials processing to weaponry and communication. As a part of the manufacturing processes, this technology helps with the cutting and welding of lightweight materials like titanium for aircraft and spacecraft construction. Additionally, laser marking enables high precision, quality control, and traceability.

The defense sector uses laser technologies in rangefinders, missile defense systems, and directed energy weapons. These systems enhance accuracy and efficiency in military operations. The technology has great potential for developing advanced systems for strategic applications in the future.

Environmental And Energy Sector

Laser processing technologies can also help the environment by driving innovation in the environmental and energy sectors. From resource management to renewable energy production, it can serve many purposes. For example, LIDAR (Light Detection and Ranging) systems are widely used in forestry management, environmental studies, and urban planning.

The energy sector can use lasers for precision cutting and processing of batteries and solar panels. Overall, the technology is eco-friendly as it serves as a clean energy source to improve processes without burdening non-renewable resources. From manufacturing to processing, it can drive sustainability in industries.

The Bottom Line

Laser processing solutions create new opportunities for innovation across different industries. These applications are only the tip of the iceberg because the potential of this technology is far greater than it seems. Ongoing research promises to deploy it in a bigger and better way to enhance efficiency, sustainability, and quality in the long run.

Read Also:

Comments Are Closed For This Article