Unlocking Efficiency: 6 Manufacturing Analytics Tips

3 Mins Read

Published on: 09 August 2023

Last Updated on: 19 September 2023

toc impalement

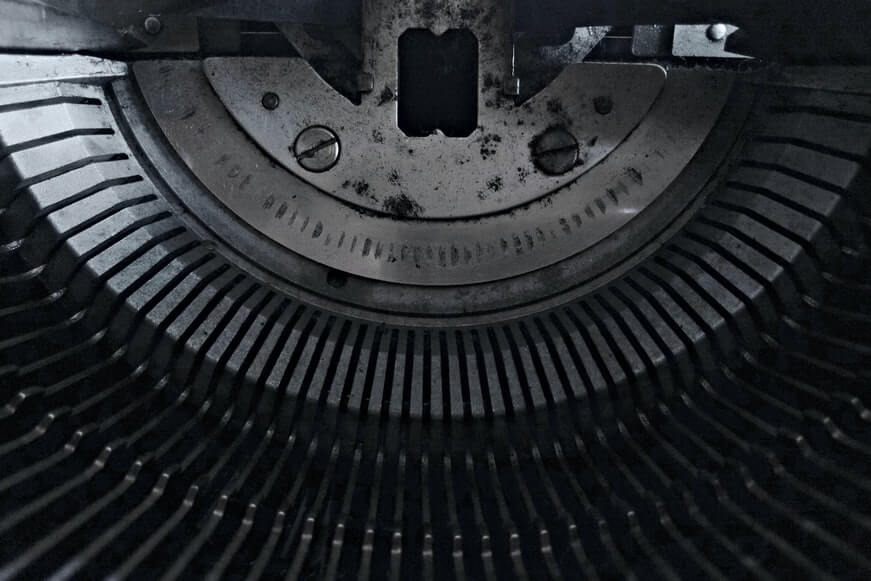

When you’re steering the ship of a manufacturing business, sailing with efficiency is your ticket to staying ahead in the race. Every cog in the wheel, every choice you make, every resource you deploy counts. That’s where manufacturing analytics step in – they’re like your trusted compass, guiding you toward smoother operations and smarter decisions.

To give you an idea, here are six tips that let you tap into the magic of manufacturing analytics and unravel a new level of efficiency across your manufacturing realm.

Core Analytics For Manufacturers

Picture this: core analytics for manufacturers are like the building blocks of a solid foundation. They involve gathering, crunching, and decoding data from different stages of your production line. This number-crunching wizardry helps you unearth bottlenecks, simplify processes, and pump up productivity. Think of it as a magnifying glass that uncovers hidden treasures in your operations, equipping you with the wisdom to steer your ship in the right direction.

Embrace Data-Driven Decision Making

In the dynamic world of manufacturing, gut feelings can be as risky as sailing blindfolded. That’s where data-driven decision-making comes to the rescue.

Every move you make should have data as its co-pilot. Whether you’re tweaking production schedules, fine-tuning inventory levels, or charting supply chain routes, data should be your guiding star, ensuring you navigate uncharted waters with confidence.

Monitor Key Performance Indicators (KPIs)

Imagine KPIs as the pulse of your manufacturing heartbeat. They’re the indicators that reveal how well your operations are humming along.

Tracking KPIs – like how quickly your products come to life, how efficiently your machinery runs, and how many defects sneak in – unveils the story of your operations. These metrics not only help you spot areas in need of a boost but also guide your course toward smoother waters.

Predictive Maintenance

Ever wished you could predict when your equipment might take an unscheduled vacation? That’s predictive maintenance for you.

By diving deep into data from sensors and machines, you can foresee maintenance needs before they turn into full-blown headaches. This proactive approach prevents unexpected downtime and adds years to your machinery’s lifespan – it’s like waving a magic wand over your equipment.

Supply Chain Optimization

Imagine your supply chain as a well-orchestrated dance. Every partner needs to be in sync for the performance to dazzle. Delving into supply chain data helps you fine-tune the moves. Balancing inventory levels, trimming lead times, and tightening the cost belt become second nature.

This symphony of data insights ensures your products hit the stage right on cue, keeping the audience – your customers – cheering for more.

Continuous Improvement Through Analytics

Picture this: the road to manufacturing excellence isn’t a one-way street; it’s a scenic route with many stopovers for improvement.

Regularly dissect data, spot trends, and embrace change. This cycle of constant refinement keeps your operations sharp, agile, and ready to tackle whatever market winds blow your way. The journey towards efficiency is a marathon, not a sprint – and analytics is your running shoes.

Remember, keep your data safe from cybersecurity threats.

Read Also:

Comments Are Closed For This Article