3 mind-blowing manufacturing processes that are used in the world around us every day

3 Mins Read

Published on: 02 February 2021

Last Updated on: 13 November 2024

We have reached the stage where we more or less take technology for granted. From photoreal CGI in movies to the incredible mobile devices we hold in our hands and use every day, it takes a lot to make us stop and go “wow.”

However, there are processes used in the manufacturing industry that some might still find hard to believe. Here is an overview of three manufacturing processes that are used every day. The first of these is quite well known; however, it doesn’t stop you from looking at it wondering how it could be “for real.”

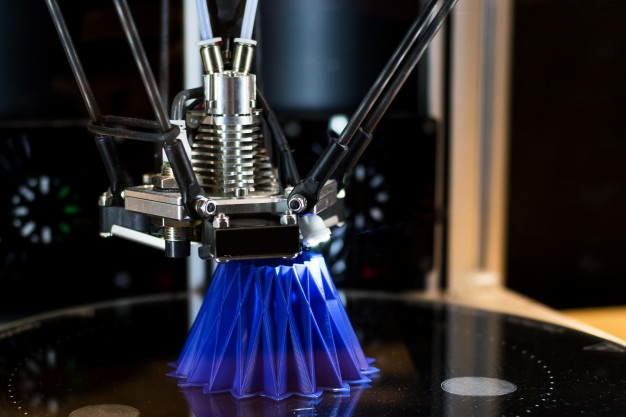

1.3D-Printing:

While it’s a term that’s often bandied about, and 3-D printers have made it into a few homes, for some, the idea of an object appearing out of thin air (very slowly) still seems like science fiction.

How it actually works is by creating a physical object from a three-dimensional CAD model and then laying down thin layers of material one after another until the object is complete. This process is also known as additive manufacturing, which doesn’t sound nearly as impressive as 3-D printing.

The applications for this technology are almost boundless, but, those who joke that the first item they’ll make with a 3-D printer is another 3-D printer are slightly ahead of what is easily possible these days.

2. Plastic Welding:

Repairing damaged plastic equipment, or joining together plastic pieces is achieved using a process known as plastic welding. This task is a specialist manufacturing process and is not often performed outside of an industrial environment.

This is mainly due to the level of preparation needed for surfaces involved, and the specialist tools and materials needed to complete the task correctly.

The pieces to be joined together have to be clean and free of rough edges, then a welding tool and welding rod (both available from a specialist supplier such as hotairtools.com) are used to join the two pieces together in a continuous line. Only similar plastics can be joined together, and the welding rod has to be of the correct material and thickness to provide a strong weld.

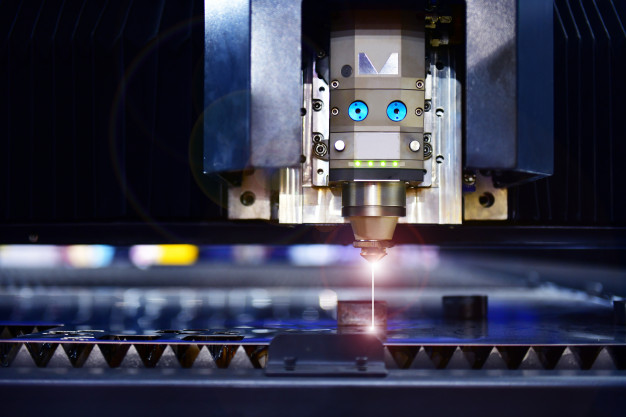

3. Water Jet Cutting:

Again, we have seen this before on television, (and certainly on YouTube), but the idea of cutting a plastic bottle, a tree, or even a sheet of metal in half doesn’t quite seem credible.

The answer is of course that the water is delivered at such high pressure, and for tougher jobs, an abrasive such as garnet is added to cut through materials like stone, ceramic, thick plastic, steel, or aluminum.

For softer materials like wood, however, a standard water jet cutter is all that is required. The uses for this technique are many, especially as there is no heat created during the cutting process, which can affect the materials being cut through.

This technology and these techniques are used in the world around us every day, but because they usually occur in a lab or a manufacturing facility, they are often overlooked as the incredible game changers they have proved to be.

Read Also:

Comments Are Closed For This Article