Precision in Manufacturing: What It Is and Why It Matters

5 Mins Read

Published on: 17 November 2023

Last Updated on: 06 February 2025

toc impalement

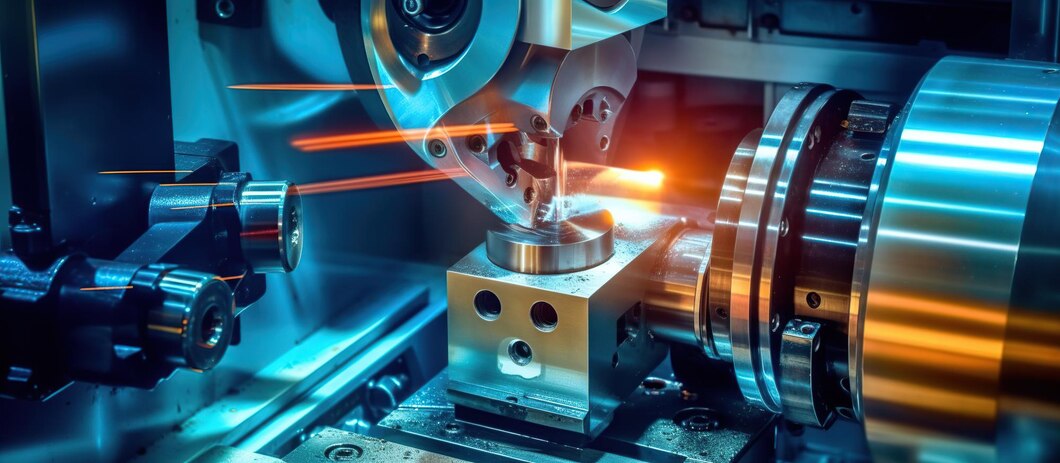

Precision in manufacturing is a critical aspect of the production process that ensures products meet or even exceed design specifications with a high degree of accuracy. It involves meticulously controlling every detail of the manufacturing process, from the selection of raw materials to the final assembly and inspection of the finished product.

According to one study, 65% of product failures are caused by poor specification and design issues. Therefore, precision is important, especially in aerospace, automotive, electronics, and medical devices, where even the slightest deviation from the intended specifications can result in catastrophic consequences.

Let’s expound on everything you should know about precision in your manufacturing business.

What Is Precision In Manufacturing?

Precision in manufacturing refers to the degree of accuracy and consistency with which a product or component is produced. It defines the ability to consistently produce products that meet exact specifications and quality standards.

Precision is a critical concept in the manufacturing industry, as it directly affects the final product’s quality, performance, and reliability. Hence, precision is achieved through a combination of advanced techniques, careful control of various parameters, and high-quality tools and equipment.

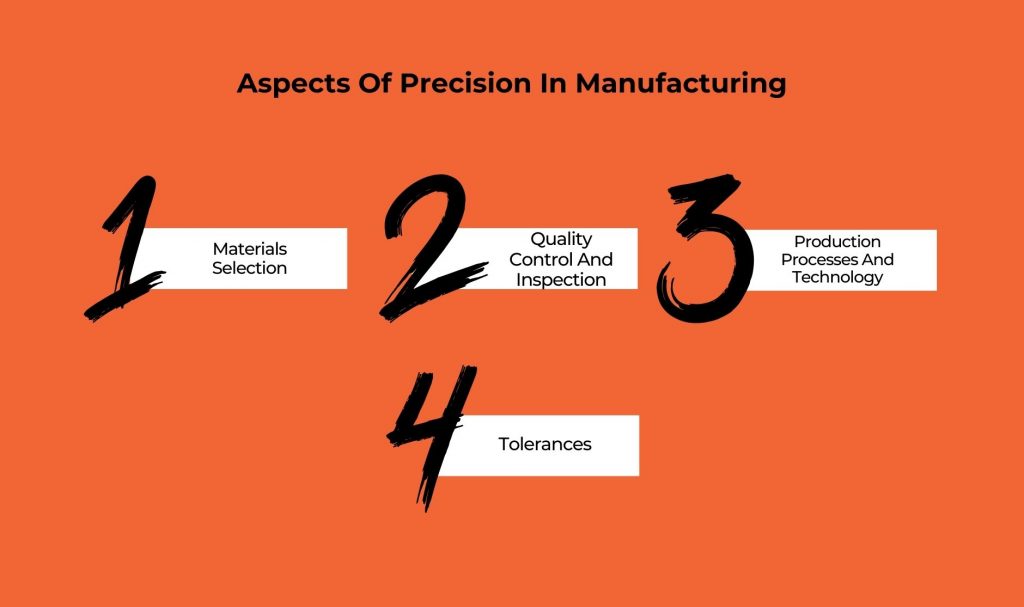

Aspects Of Precision In Manufacturing

Manufacturing plays an important role in deciding the quality of a material. However, various aspects must be checked to ensure a smooth manufacturing process. Here are a few significant considerations:

Materials Selection

The choice of materials plays a crucial role in achieving precision. Precision engineers work with various advanced materials, including high-strength alloys, ceramics, and polymers. You should use high-quality materials with consistent properties. Consequently, it ensures that the final product meets the desired specifications. Sometimes, you might need specialty materials to meet specific precision requirements.

Quality Control And Inspection

Quality control and inspection processes are integral to maintaining precision in your manufacturing business. Perform rigorous quality control measures and inspections throughout the manufacturing process to detect any deviations from the specifications.

Use advanced measurement tools, like coordinate measuring machines (CMMs) and optical comparators, to verify that the final products meet the desired specifications. Furthermore, deploy statistical process control (SPC) to monitor and maintain consistency throughout the production process.

Production Processes And Technology

Precision is maintained during the manufacturing processes, which can involve cutting, molding, welding, and assembly. One must closely monitor these processes to ensure each step meets the required standards. Precision engineering leverages state-of-the-art manufacturing techniques to achieve high precision and consistency in component production.

However, investing in all the necessary precision tools can be financially draining. It often makes financial sense for companies to outsource short-term precision manufacturing projects to save money and time.

For example, suppose you have precision grinding projects in your manufacturing firm. In that case, you can simply find a company offering precision grinding services near you to ensure that the work is performed by experts skilled in achieving tight tolerances and high-quality surface finishes.

The basic necessity is to get quality services without incurring extra capital investment. Moreover, there are no ongoing maintenance costs as well as training expenses.

Tolerances

Tolerances refer to preset limits within which your product’s dimensions, properties, or performance must fall. Precision engineering demands extremely tight tolerances, often in the micrometer or nanometer range.

However, tight tolerances call for a high level of precision, as even small deviations can lead to product defects. It is therefore necessary to design the components using tolerance software supplied by a provider like Sigmetrix and manufacture them to high standards in order to avoid deviations from specified dimensions, thus ensuring optimal performance and reliability.

Why Precision In Manufacturing Matters?

When it comes to manufacturing, efficiency is not a big factor. If you think alike, you might be wrong. Here are a few reasons that state the importance of manufacturing precision.

Product Quality

Precision is paramount in manufacturing as it directly impacts product quality. Products with tight tolerances and exact specifications are more likely to meet customer expectations and adhere to industry standards.

Whether it’s a precision-engineered automotive component or a microchip for electronics, slight variations can lead to product defects, recalls, and, ultimately, dissatisfied customers. This is essential for industries like aerospace and medical devices, where any deviation from the norm could have life-threatening consequences.

Cost Reduction

Precise manufacturing can lead to cost savings in various ways. It minimizes waste and defects, hence companies can reduce their material and energy consumption. Moreover, precision manufacturing allows companies to design products with fewer components, reducing assembly and maintenance costs. This not only improves the bottom line but also enhances a company’s competitive edge.

Efficiency And Throughput

Precision in manufacturing processes leads to improved efficiency and increased throughput. Machines and automated systems can operate at their maximum capacity when one calibrates and maintains them with precision. This results in faster production cycles reduced downtime, and increased overall productivity.

Innovation And Market Competitiveness

Precision is at the heart of innovation in manufacturing. It allows companies to create cutting-edge products that require exacting specifications. With this highly competitive market, the ability to manufacture intricate and complex components with precision can give your company a competitive edge. Precision also opens the door to new materials and technologies, fostering innovation and driving industry advancement.

What Does The Future Of Precision Manufacturing Mean?

The future of precision manufacturing is bound to be bright. This is primarily because this manufacturing process increases general precision and feasibility. As a result, the scope of human intervention is lowered to a great extent.

As a result, expect to see this form of manufacturing across different sectors like automobile, medicinal, etc. This is why, many business experts believe that this is the next step forward.

Couple that with AI, and you have a robust manufacturing precision that will be unparalleled for many years to come.

Wrapping Up

In a nutshell, precision engineering can be quite a worthwhile investment for your manufacturing business. The secret to long-term precision in manufacturing is to invest in cutting-edge technologies and expertise, which frankly can be challenging and may even require substantial investments. That said, you can always engage a reputable precision service provider rather than try to do everything in-house!

Read Also:

Comments Are Closed For This Article