How will Process Free Plates all set to change the printing landscape?

7 Mins Read

Published on: 15 July 2023

Last Updated on: 15 November 2024

toc impalement

Technological advancements have significantly changed various industries, including the printing industry. One such innovation that has gained attention and is vital in promoting sustainability is the introduction of process-free plates.

The article will explore the concept of process-free plates, understand how they work, and delve into their numerous benefits and impact on the environment.

By understanding the significance of process free plates in the printing industry, you can appreciate their role in driving sustainable practices.

How Digital Printing Works?

Hold up. Let us not rush. Let us start slow and understand the basics first. Before we delve deep and learn all kinds of things about process-free printing, let us understand how digital printing works in the first place.

Digital printing is generally segregated into two different methods: inkjet printing and laser printing. Both of these methods work similarly. They either use a laser to burn an image onto the page or they use ink to print on paper.

What are Process-Free Plates?

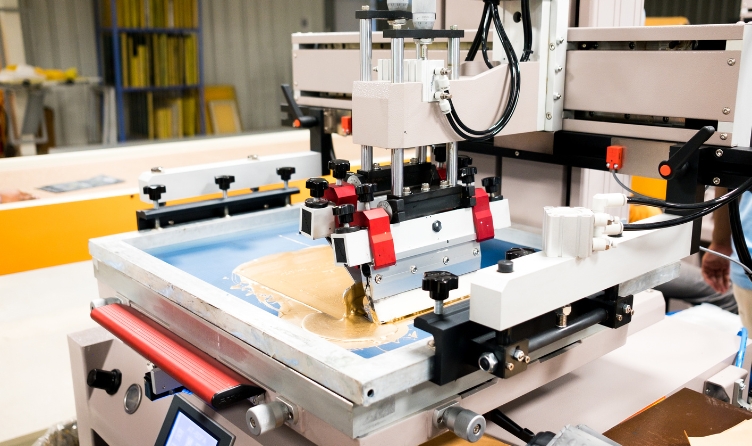

Processless plates are innovative types of printing plates that do not require chemical processing in their production or during printing.

Unlike traditional plates, which involve multiple stages of development, washing, and drying, process-free plates simplify the printing workflow.

They can be directly imaged on the press, eliminating the need for intermediate processing steps. Processless plates are typically based on either thermal or photopolymer technology.

Thermal process-free plates utilize heat from a laser diode to expose the image onto the plate’s surface. The exposed areas become receptive to ink during printing, while the non-image areas repel ink, resulting in the desired image on the printed material.

On the other hand, photopolymer process-less plates use light exposure to create the image. These plates have a photosensitive layer that reacts to UV light, causing a chemical change in the plate’s surface.

The exposed areas become ink-receptive, while the unexposed areas remain ink-repellent, resulting in high-quality image reproduction.

Benefits of Process-free Plates:

Process-free plates offer numerous benefits, making them a sustainable choice for the printing industry. One significant advantage is the elimination of chemical developers and processing equipment.

This reduces costs and minimizes the environmental impact associated with traditional plate processing. The absence of chemical developers also reduces the risk of hazardous waste generation, creating a safer working environment for employees.

Another notable benefit is the simplification of the printing workflow. Without intermediate processing steps, process-free plates contribute to faster plate production and setup, ultimately leading to quicker turnaround times. This advantage is precious for time-sensitive printing projects such as newspapers or magazines.

Environmental Impact of Process-Less Plates:

The environmental impact of process-less plates is a crucial aspect to consider. Traditional plate processing involves using chemicals, such as developers and fixers, which can harm the environment if not handled properly.

These chemicals can contaminate water sources and contribute to air pollution during their manufacturing and disposal processes.

By eliminating the need for chemical processing, process-free plates significantly reduce the environmental footprint of the printing industry.

The absence of chemical developers means less water consumption and waste generation.

Additionally, reducing energy consumption during the plate processing stage further contributes to minimizing carbon emissions and conserving natural resources.

Cost-Efficiency and Long-Term Savings:

Processless plates offer cost advantages to printing businesses. Although the initial investment in process-less plate technology may be higher than in traditional plates, the long-term savings outweigh the upfront costs.

Eliminating the need for chemical developers and processing equipment reduces ongoing expenses, such as purchasing chemicals and maintaining processing machinery.

Furthermore, the increased efficiency and faster turnaround times achieved with process-less plates can lead to higher productivity and revenue generation. Printers can accommodate more jobs within a given timeframe, allowing them to serve a larger customer base and increase their overall profitability.

Print Quality and Consistency:

Processless plates are known for their exceptional print quality and consistency. The absence of processing steps minimizes the chances of plate contamination, resulting in cleaner images and sharper details.

This advantage is particularly crucial in industries that require high-quality printing, such as packaging, advertising, and publishing.

Moreover, processless plates offer better plate-to-plate consistency. Traditional plate processing can introduce variations in the plate’s surface, leading to consistency in print quality from one plate to another.

With process-free plates, the imaging process is more controlled, resulting in consistent print quality throughout the print run.

Tradeoffs Of Process-Free Printing

Like everything in this world, there are some tradeoffs to procuring state-of-the-art process-free plates. While they have some amazing benefits that really set them apart. However, they also come with some challenges.

Hence, you must know about these limitations as well. Otherwise, you will be harboring half-baked knowledge. Therefore, here are some of the most prominent tradeoffs or cons of process-free printing.

Paper Wastage

One of the biggest and most alarming aspects of process-free plates is their heavy paper wastage. These plates can be really wasteful in terms of paper. On the contrary, manufacturers claim that these plates do not waste material and are actually not wasteful. However, that is farthest from the truth.

Sub-Par Image Quality

The next problem that you might face with process-free printing is the sub-par image quality. This means the quality of printing is sub-par. In fact, in some cases the image can come off so light that it feels invisible. Therefore, these are two of the most prominent trade-offs of Process-free plates and printing.

Integration of Process-Less Plates in the Printing Industry:

The adoption of these plates is steadily increasing in the printing industry. Print service providers are recognizing the environmental and economic benefits of these plates and incorporating them into their printing processes. The advancements in process-less plate technology have made them more reliable, efficient, and compatible with various printing presses.

Manufacturers are also investing in research and development to improve process-less plate technology further. Ongoing innovation aims to enhance print quality, extend plate life, and optimize the plates’ performance for different printing applications. As a result, process-free plates are becoming more versatile and accessible to various printing businesses.

Industry Challenges and Future Outlook:

While they have shown immense potential, challenges still need to be addressed. One significant challenge is the limited availability of compatible printing presses.

Not all printing presses can accommodate process-free plates, requiring some printers to make additional investments in upgrading their equipment.

They may have specific limitations regarding run length and durability compared to traditional plates. Printers need to consider the particular requirements of each printing project to determine if they are suitable.

However, with the ongoing advancements and growing demand, these challenges are expected to be addressed in the future. The printing industry is constantly evolving, and process-free plates are poised to shape its sustainable future significantly.

Implementing Process-Less Plates:

While these plates offer numerous benefits, their implementation in the printing industry is not without challenges. One of the significant obstacles is the limited availability of compatible printing presses.

Not all printers have the equipment required to accommodate process-less plates, making it necessary for some businesses to invest in upgrading their machinery. However, as the demand for process-free plates grows, manufacturers are working towards developing more compatible options that can be seamlessly integrated into various printing setups.

Another challenge lies in the durability and run length of process-less plates compared to traditional plates. Process-free plates may have certain limitations in terms of longevity, particularly for longer print runs.

Advancements in Process-Less Plate Technology

The printing industry is a dynamic field where technology constantly evolves. Advancements in process-less plate technology are being made to enhance their performance and expand their capabilities.

Manufacturers are investing in research and development to address the challenges of process-less plates, such as compatibility and durability.

Innovations in imaging technology, plate materials, and coating techniques aim to improve print quality, extend plate life, and enhance the versatility of process-less plates.

These advancements contribute to making process-free plates a more viable and sustainable option for printing businesses, further solidifying their role in the future of the industry.

Industry Adoption and Environmental Responsibility

The adoption of these plates is driven by their numerous benefits and the growing emphasis on environmental responsibility. Printing companies recognize the need to reduce their ecological footprint and actively seek sustainable alternatives to traditional printing methods.

Process-free plates provide a viable solution that aligns with their environmental goals while maintaining high print quality and efficiency.

Furthermore, as consumer awareness about sustainability increases, businesses are pressured to demonstrate their commitment to eco-friendly practices.

By implementing process-free plates, printing companies can showcase their dedication to reducing chemical waste, conserving resources, and promoting a cleaner and healthier environment.

The Future of Process-Less Plates

Looking ahead, the future of these plates appears promising. As technology advances, the challenges associated with its implementation will likely be overcome.

Process-free plates are expected to become more widely accessible and compatible with various printing presses, eliminating the need for costly equipment upgrades.

Moreover, as the demand for sustainable printing practices grows, the market for processless plates will expand. Manufacturers will continue to invest in research and development to enhance the performance and durability of these plates.

As a result, process-free plates will become a mainstream choice in the printing industry, contributing to a more sustainable future.

Conclusion:

Process-free plates represent a revolutionary innovation in the printing industry, offering a sustainable alternative to traditional plates.

They eliminate the need for chemical processing, resulting in reduced environmental impact, cost-efficiency, improved print quality, and streamlined workflows.

While challenges exist, ongoing advancements in process-less plate technology are overcoming these obstacles and driving widespread adoption.

The printing industry is transforming sustainability, and process less plates are at the forefront of this change.

By embracing these plates, printers can reduce their ecological footprint, demonstrate environmental responsibility, and meet the demands of a market that increasingly values sustainability.

Read Also:

Comments Are Closed For This Article